- Introduction

- Asia / Islam

- Europe & Britain

- French Origins

- Stylus-Quill-Penner

- Early Fountain Pens

- Hawkins-Mordan Patent

- Virginia Roots

- Jefferson Pen Analysis

- American Pencil Makers

- American Gold Pen Makers

- Gold Pen Advertising

- Philip Poole ‘HIS NIBS’

- Inkwells

- Inkwells & Writing Sets

- Writing Sets

- Cyphers

- French Inkwell Makers

Bagley Manufacturing Locations 1840s-1850s

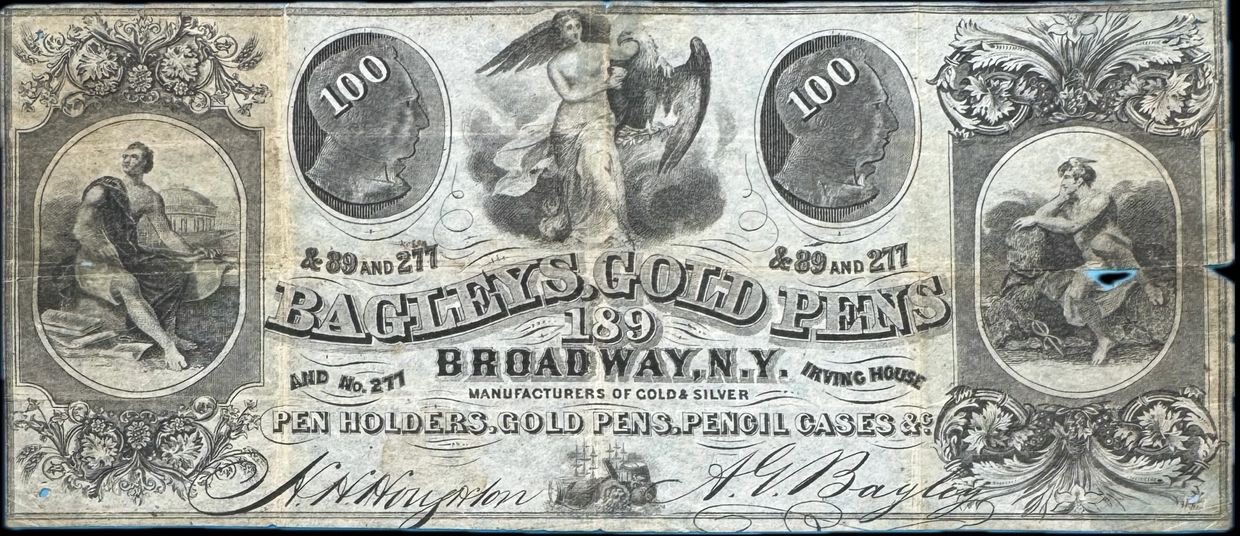

Bagley Gold Pens Advertising Bill

Mr. Bagley's Gold Pen manufacturing operations in New York City were spread across five different locations during the early to mid-1850s.

These locations included a boutique retail outlet at Washington Irving House near Union Square, and manufacturing operations on Broadway in Manhattan's Lower East Side, on Maiden Lane next to Platt Brothers Gold & Silver Exchange, on Broadway in Tribeca, and finally at 89 Broadway in the bustling Wall Street Financial District. Other smaller boutique retail locations may have also been present in the City.

This vast network of locations demonstrated the significant scale of Bagley's operations, which far surpassed other Gold Pen manufacturing ventures.

These boutique and manufacturing operations location were aside from a large variety of stationers and others reselling Bagley goods.

Read About Bagley’s Factory in 1851

Gold Pen Nib & Extension Pen Case Manufacturing Operations

The Gold Pen - Its History - the Method of its Manufacture

The Weekly National Intelligencer, Washington City Saturday July 5, 1851

The Gold Pen - Its History - the Method of its Manufacture - the Condition of the Business in this Country

New York, June 24, 1851.

Albert G. Bagley Background

A. G. Bagley, a Vermont mechanic, bred to the trade of a watchmaker, first made the gold pen in the United States in 1838 taking up the trade without previous instruction, and placing the name of Hawkins on his work. Soon afterward he became the foreman in the shop of Levi Brown, which was the first considerable gold pen factory established in this country.

Bagley Gold Pen Nibs Became World Renown

Bagley, whose pens are now more widely known than those of any other maker in the world, not long afterwards commenced an extensive establishment in his own name, and has carried on the business to this day, being now in connection with H. H. Houghton, Esq., formerly well known here as an accomplished and popular North River steamboat officer.

Author W.D.W. Explains Why Bagley’s Factory was Chosen

Having tested his work by using one of his pens constantly for four years in writing for the press, in which employment I wrote probably four times as many words as any clerk in the Union at the same time, I selected his factory in which to obtain a knowledge of the process of making the pen, which is as follows:

The Bagley Gold Pen Nib Manufacturing Steps

The Gold American Eagle Coin was minted as early as 1792

The gold, in eagles, is first melted into ingots, weighing from seventy to eighty ounces of the quality to give the proper elasticity, and then pressed, by being passed through a series of rollers, into sheets, about one thirty-seconds of an inch in thickness.

Cutting the Gold Pen Nib Blanks

The Gold Pen Nib Blanks are then cut with great rapidity by machine into blanks, or pieces of the proper length, size, and shape. The Blanks are next passed through a circular filing machine, which slits an opening in the gold to receive the iridium point.

Iridium Application & Slitting

That point is then soldered on by a careful workman. The iridium point is next "squared up," or ground roughly on a copper "lap." The pointed blank is now passed through rollers, which, by pressure, draw them out to the required length. Next, they are "planished," or "hammer tempered," to give them the proper degree of elasticity. They are then passed through a machine which brings them nearer still to the exact shape required, and impresses them with the name of the maker, "Albert G. Bagley, New York."

Bending Gold Pen Nibs to Proper Curve

Then the pen is taken to still another press, where, being laid on a steel form, two motions of the foot on a pedal instantly bends it into the elliptical or half oval form peculiar to the work of this house.

Splitting the Applied Iridium Point

Each Gold Pen Nib is now transferred to a machine, whereon it is placed, when by two motions of the foot on a pedal it is instantly slit or cut; by a steel knife, which passes rapidly over its surface. Afterwards it is taken to a small wheel, revolving with great rapidity, which, with the application of emery, saws a continuation of the split in the gold through the iridium point. This operation requires great steadiness of hand and acuteness of sight. For a year after inventing it, Mr. Bagley kept this particular machine a secret from the rest of the trade.

Bagley Manufacturing Dominance & Inventive Ingenuity Praised in 1851

I may here mention that he invented every machine peculiar to the business used in not only his own but every other American or English manufactory of gold pens.

Final Buffing & Rasping the Underside of the Gold Pen Nib

It is next cleaned by rubbing each pen by hand with Scotch stone, and then it is polished on “buff" wheels. The pens are next handed over to men, who carefully dress the iridium points, by passing over emery laps or wheels, to take off any inequalities in the point. They are then fine ground on a little copper lap, which, being driven by the foot, makes from three thousand to four thousand revolutions per minute. This is the most tedious process in the manufacture the workman being obliged to keep a magnifying glass at his eye while engaged on it. Afterwards they are "rouged" or colored, and then they are rasped on the inside to make them retain the ink.

Testing Each Finished Gold Pen Nib

The Raspers next hand back the pen to the last grinder, who retouches the points on his lap," examines the whole pen carefully with the eye glass and tests each Gold Pen Nib on paper.

Final Inspection & Distribution Release

The Gold Pen Nibs are then taken from the factory to the office, and each examined through a still more powerful magnifying glass, and triad with ink those proving in the least imperfect being returned to the factory, to be refinished or broken up, while those which the firm are willing to have go forth bearing their mark are thenceforth "in the market."

Bagley Trade Secret Steps Remain Undisclosed

There are two or three processes used by this house which they decline disclosing so I cannot describe them to your readers.

Rhodium versus Iridium for Gold Pen Nib Points

In this shop no rhodium is used for points, but a somewhat similar metal, styled iridium, perhaps ten times as durable, which is likewise found in the platinum mines of Siberia principally. Until thus applied, both these metals were regarded as utterly valueless, I understand, and great care was taken to prevent their incorporation in the manufacture of coin.

The iridium will not yield to fire, or to any known acid or acids while the rhodium is fusible at a very high heat. They both look like small particles and scales of cast steel. The trade purchase the rhodium at from eight dollars to ten dollars per ounce, while the iridium costs them thirty to one hundred and fifty per ounce. Even in the best lots of the latter, not more than one particle in ten is fit to put on pens of the quality manufactured by A. G. Bagley & Co. The cheapest description of nominal gold pens made, are of copper or brass, plated, and pointed with platinum. Of course, while purchasers are at hand for such Pindarish goods, workmen will stand ready to make them.

Seven Gold Pen Nib Factories in New York in 1851

There are at present seven gold pen factories in and around New York, one in Syracuse, and one recently established in Philadelphia, which comprise all in operation in the United States. Those in this immediate vicinity employ about three hundred hands, all of whom are males. It will be safe, therefore, to write down three hundred and fifty as the number of workmen engaged in supplying the home and foreign demand for the American gold pen.

Continuation of the article below:

Bagley Extension Pen Case Manufacturing Steps

Bagley & Co. employ some forty hands and work up weekly an average of $1,000 worth of gold, silver, and iridium, using American coin alone.

Bagley Patents in Operation

The silver is used in their manufacture of the cases, for which they hold the only patents now existing in this country. These inventions both have for their object the purpose of shortening the case, to make it more portable in the pocket [referring to patent no. 4,557 awarded in 1846 and patent no. 6,981 awarded in 1850].

Bagley Pencil Extra Lead Storage

The first section makes a place for the ever-pointed leads in the head of the part which was formerly occupied wholly by the machinery by which the leads are screwed down, to be always ready for use. This enables the manufacturer to dispense with so much of the length of the case as formerly was necessary for carrying the spare leads, immediately next to the seal.

Bagley Extension Case Protects Gold Pen Nib

The other patent processes consist of making the case of four tubes. The outer and the third are joined at the bottom the second inserted between these, being pulled out from the top when using the pen; the fourth carries the pen itself, which, when put away reversed, is protected by the third tube from contact with the one pushed down, and thus saved from the injuries to which before it was constantly subjected. In this manner Bagley has managed to make his largest size recording pen, such retail for $8, in a plain silver case, double or slide, with perfect security to the point, into a length of three inches.

Bagley Extension Pen Case Manufacturing Steps

Ingots to Tubes

His processes for the manufacture of the gold and silver cases are also of great interest to the reader who desires information. The silver coin is first melted into ingots of suitable dimensions, and then rolled between presses to the required thickness and width when it is next turned up on a steel cylinder and soldered into tubes.

Drawing According to the 4991 Patent

Rods are then inserted into these tubes, and placing them on a mandrill, with holes bored through the drawplate of decreasing dimensions, they are drawn by machinery down to the required diameter and thickness, their length increasing of course.

Fluting, Chasing, & Barleycorn Engraving

The tube being next cut into pieces of the desired length, they are placed on a small rod, in a machine, and pressure being brought to bear on them by the use of a lever worked with a pedal, they are in instantly fluted. The chasing of the heads and rings is beautifully and quickly accomplished by a very small machine into which they are inserted, when proper dies are brought to bear on them, which press the metal into the fanciful forms desired.

The most singular process in this branch of the business is that of putting on or cutting the “watered" ornaments of the unfluted cases. This is done with a very complicated machine, not more than one and a half foot in bulk square, wherein a cutting tooth scratches on the case any form of device or “watering" desired. It contains a great many wheels and other combinations removable at pleasure, some of which are changed as often as a different design is required to be worked, with the single cutting tooth thus made to move eccentrically. It works with great rapidity, and never fails to discharge its office, cutting Tetters, flowers, or graceful combinations of curves, or straight lines, as may be required, with more rapidity and accuracy than one can conceive who has not witnessed its operation. This is the only machine of the particular kind that we know of in the world -- Mr. Bagley, by whom it has been brought to its present remarkable perfection, doing his best to keep the secret of its multifarious arrangements to himself. Its “barley corning" is said to be deeper, more regular and distinct, than any other similar machine-engraving executed in either hemisphere.

Bagley Product Distribution

But I must hasten on. In 1840 gold pens first became an article of commerce in the United States, and already they are exposed for sale by every stationer, and almost every jeweler and watchmaker, from Bangor to San Francisco being, as it were, as necessary stock in such trade as “domestics" in that of the dry goods dealer.

There are “none, to speak of," imported but, on the contrary, large quantities are sent, at least by the house of Bagley & Co., abroad.

If your Washington readers will for an instant reflect on the probable number for sale in your city, and then remember that they are, in use everywhere in the United States as extensively as with you, they will get an idea of the rapidity with which they are turned out -- only about three hundred and fifty hands in all being employed in their fabrication.

Bagley Factory Filled Global Orders

The house of Bagley & Co. makes none except to order, either for jobbers here, for American and foreign merchants, or for individuals.

They thus fill heavy orders from London, Paris, Germany, Spain, China, South America, and Mexico.

When I was in their counting room yesterday, they were packing an invoice just made to fill an order from Sierra Leone Besides their factory (which is in the upper story of a huge iron building on Duane Street) they have an establishment in the lower part of Broadway for wholesaling;, and one of the most magnificent stores under the Irving House, opposite Stuart's, where they supply their city customers.

This last is the only establishment in the city exclusively appropriated to selling gold pens singly; the city demand for their work being much more general than for any other such pens. It is said that they may thank for this preference their use of iridium instead of rhodium, their particular skill in cutting the points and shaping the pen so as to give it great strength and elasticity, Bagley’s patents for saving space in the handles, effectually preventing injury to the pen in the case, and Bagley’s beautiful little machine for “watering" ornaments on the case, which works so like a thing of life and will.

Bagley Trained the Trade Workforce

A. G. Bagley, by whose side and under whose instructions more than half the mechanics in the Union engaged in the business learned the trade, who, as before remarked, invented every machine in use peculiar to the business, is not yet thirty-seven years of age. Though so young, he has already lived to see his country rank the first in the world in an article of commerce which he may be said to have established for it. That this remark is emphatically true may be drawn from the fact that his house sends to Paris alone, on special orders, more gold pens than are imported from Europe into every part of the United States.

Bagley to Mallat Ink Reserve Comparison

I may add that those which are imported into the United States are all made in Paris, where a lip or elliptical bow [referring to the French Mallat Brevete Pen] is placed on the inside of the pen, in order to make them hold as much ink as possible. They do not “go down" here; the inside rasping applied by Bagley being found best adapted to attain the desired end.

W.D.W.

The original published story was authored by William Douglas Wallach (1812 – December 1, 1871) who was an American surveyor and newspaper entrepreneur. Born in Washington, D.C., he earned a civil engineering degree at Columbia College and moved west doing survey work, reaching the Republic of Texas in 1838 where he supported Sam Houston and the annexation of Texas to the U.S.

Photo Gallery

Copyright © 2023-2025 JOHN B. MINOR - All Rights Reserved.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.